Alright, let’s talk about those big, fat pipes you see on two-stroke engines. It’s something I puzzled over myself back when I was first really getting my hands dirty with these things. Wasn’t just reading about it, I was living it in my garage.

I had this old RM125 project bike. Thing was beat up, but the engine had potential. One of the first things I noticed, plain as day, was the exhaust pipe. It wasn’t just a pipe, it was this big, bulbous thing, then it got skinny again near the end. Totally different from the straight-ish pipes I’d seen on four-stroke bikes.

My first thought was, why? Is it just for noise? Seems like a lot of metal just to muffle the sound. So, I started poking around.

Getting Hands-On

First thing I did was take the pipe off. Held it up. It was surprisingly light for its size, told me the metal wasn’t super thick. Looked inside as best I could with a flashlight. You could see the chamber expanding out and then smoothly coming back in. Not just a random shape, it felt deliberate.

I remember cleaning it out. Lots of oily gunk in there, typical two-stroke stuff. While cleaning, I was thinking about how a two-stroke works. Intake and exhaust ports open at roughly the same time down near the bottom of the piston stroke. That seemed messy, like fresh fuel mix could just shoot straight out the exhaust port before it even got burned.

That’s when the lightbulb started to flicker. What if that big pipe wasn’t just letting exhaust out?

The ‘Aha!’ Moment

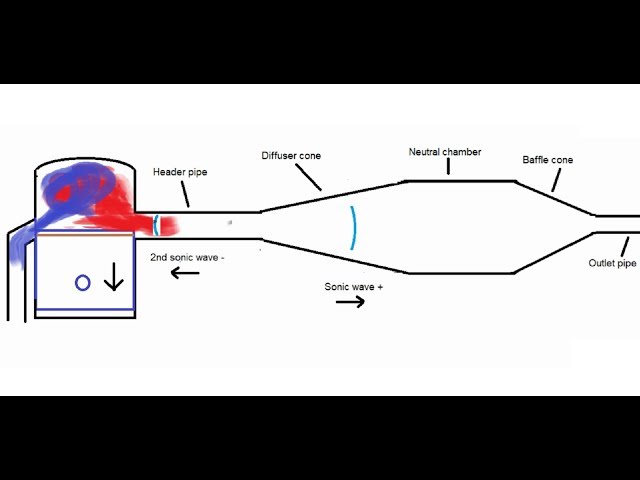

I started thinking about sound waves, pressure pulses. You know how when you shout into a tunnel, the sound bounces back? The engine’s firing creates this massive pressure pulse, a bang, that shoots down the pipe.

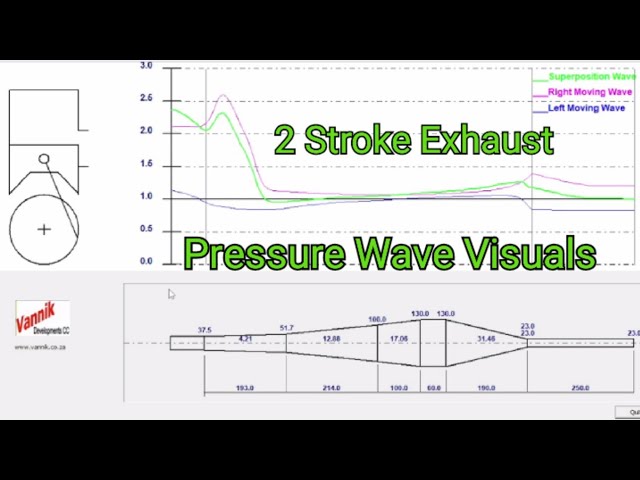

- When this pulse hits that big open chamber part, it expands, slows down, and kind of reflects back, but as a weaker, suction-type wave first. This helps pull the leftover burnt gases out of the cylinder. Good start.

- But then, as the pipe narrows down again towards the end, that initial strong pressure pulse hits that taper and reflects back towards the engine as a positive pressure wave.

Now, here’s the cool part I figured out, just visualizing it in my head while looking at the parts: This returning positive wave needs to arrive back at the cylinder just as the piston is closing the exhaust port, but while the intake ports are still open.

What does it do? It literally stuffs any fresh fuel/air mix that was trying to escape out the exhaust port right back into the cylinder before the port closes! It’s like a little invisible helper pushing the good stuff back in.

Putting it Together

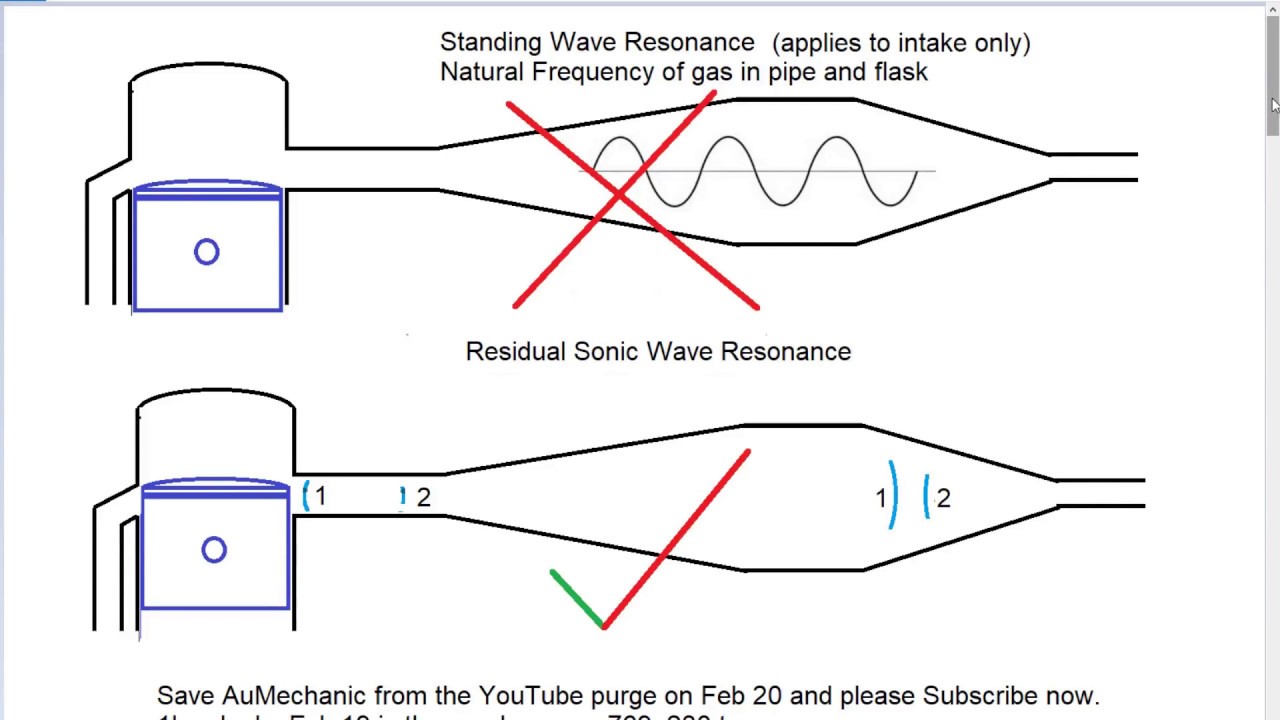

So, that big weird shape isn’t random at all. It’s timed. The length of the straight part, the angle and volume of the expansion chamber, the angle and length of the final cone – it’s all tuned. Tuned to make that pressure wave bounce back at just the right moment for a specific RPM range.

That’s why changing the pipe on a two-stroke makes such a huge difference to where the power hits. A pipe designed for low-end grunt will have different dimensions than a pipe for screaming top-end power. It’s all about timing those returning waves.

So yeah, I didn’t just read it in a book. I got there by taking the thing apart, looking at it, thinking about how the engine actually worked cycle by cycle, and imagining those pressure waves bouncing around. That big pipe isn’t just an exhaust; it’s a critical part of the engine’s breathing and power delivery. Pretty clever stuff, really, born from necessity with those simple two-stroke engine designs.